Free Laser Engraver Files and the World of Laser Engraving Machines

Introduction to Laser Engraving Technology

Laser engraving technology has revolutionized the way we create intricate designs, personalize items, and produce prototypes. This advanced method employs high-energy laser beams to precisely etch or cut materials, offering a level of detail and accuracy unattainable by traditional methods. Whether you’re a hobbyist, small business owner, or industrial manufacturer, laser engraving machines offer versatility, efficiency, and creativity.

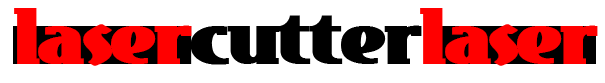

Laser Engraving Technology and Applications

Laser engraving works by directing a focused laser beam onto the surface of a material. The beam’s intensity and duration determine the depth and appearance of the engraving. This technology is used across various industries, including:

- Jewelry: Engraving names, dates, or logos onto rings, bracelets, and pendants.

- Personalization: Customizing gifts, such as mugs, keychains, and phone cases.

- Prototyping: Creating detailed models for design verification.

- Packaging: Adding branding and serial numbers to product boxes.

- Art and Crafts: Producing intricate designs on wood, leather, and glass.

The range of applications is vast, limited only by the imagination and the machine’s capabilities.

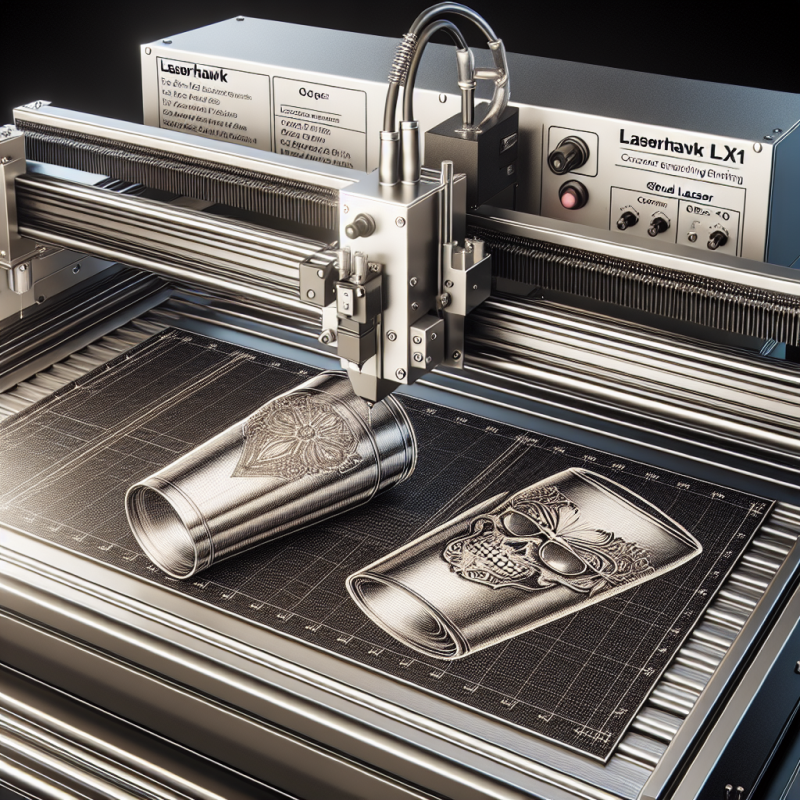

Machine Specifications and Features

When choosing a laser engraving machine, several specifications and features are crucial:

- Laser Power: Higher wattage lasers can cut thicker materials and engrave faster.

- Workspace Size: Determines the maximum dimensions of the items you can engrave.

- Software Compatibility: Ensure the machine is compatible with your design software for seamless workflow.

- Engraving Speed and Resolution: Faster speeds with high resolution maintain detail and efficiency.

- Cooling System: Essential for maintaining laser performance and preventing overheating.

- Material Handling: Features like auto-focus, adjustable beds, and vacuum tables enhance versatility and ease of use.

Modern laser engraving machines also often come with safety features such as emergency stops, enclosed work areas, and interlocks to prevent unauthorized access.

Material Compatibility

Laser engravers can work with a wide range of materials, each requiring different settings for optimal results:

- Wood: Offers a natural look and can be engraved with varying depths for texture.

- Leather: Provides a soft, tactile finish suitable for personalized items.

- Acrylic: Results in clean cuts and can be backlit for illuminated designs.

- Metal: Requires higher power lasers for marking and shallow cuts.

- Glass: Creates frosted effects and intricate patterns.

- Paper and Cardboard: Ideal for labels, invitations, and packaging.

Understanding your material’s properties and adjusting laser settings accordingly is key to achieving the desired outcome.

Safety Considerations

Operating a laser engraving machine safely involves several practices:

- Eye Protection: Always wear laser-safe glasses when working near the machine.

- Ventilation: Ensure adequate exhaust systems to prevent the buildup of harmful fumes.

- Fire Precautions: Keep a fire extinguisher nearby and have a clear evacuation plan.

- Training: All operators should be thoroughly trained in safety procedures and emergency responses.

- Machine Maintenance: Regular checks and cleaning prevent accidents caused by malfunction.

Safety should be a top priority, as laser beams can cause severe eye damage and burns.

Industry Best Practices

To maximize the effectiveness and longevity of your laser engraving machine, follow these industry best practices:

- Regular Calibration: Ensures precision and consistency in your work.

- Material Testing: Experiment with settings on scrap material before starting a project.

- Software Optimization: Use vector graphics and optimize file sizes for smoother operations.

- Backup Systems: Maintain backups of your software and critical files.

- Documentation: Keep detailed records of machine settings, maintenance, and project outcomes for future reference.

Adopting these practices will enhance your workflow and the quality of your engravings.

Cost-Benefit Analysis

Investing in a laser engraving machine requires careful consideration of costs versus benefits:

- Initial Cost: Ranges from budget-friendly hobby models to high-end industrial systems.

- Operating Costs: Include electricity, consumables like lenses and gases, and maintenance.

- Return on Investment: Faster turnaround times, increased customization options, and higher-quality outputs can boost sales and customer satisfaction.

- Scalability: Machines can grow with your business, accommodating larger volumes and more complex projects.

Weighing these factors will help you choose a machine that aligns with your business goals and budget.

Maintenance Tips

Proper maintenance is crucial for maintaining peak performance and preventing costly repairs:

- Regular Cleaning: Remove dust and debris from lenses, mirrors, and the work area.

- Lubrication: Keep moving parts well-lubricated to reduce wear and tear.

- Firmware Updates: Ensure your machine’s software is up-to-date for new features and bug fixes.

- Alignment Checks: Periodically verify the alignment of the laser beam and optics.

- Spare Parts Inventory: Keep commonly replaced parts on hand for quick repairs.

A well-maintained laser engraver will provide years of reliable service.

Project Ideas and Tutorials

With a laser engraving machine, the possibilities for creative projects are endless. Here are some ideas and resources to get you started:

- Personalized Gifts: Engrave names and messages onto items like cutting boards, wine glasses, and journals.

- Home Decor: Create wall art, coasters, and signs with unique designs.

- Business Branding: Add logos and branding elements to promotional materials.

- Educational Projects: Engrave geological samples, circuit boards, and educational tools for classrooms.

- Free Laser Engraver Files: Explore a vast library of pre-designed templates at free laser engraver files for inspiration and ready-to-use projects.

Many online communities and tutorials offer step-by-step guides, tips, and tricks for enhancing your laser engraving skills.

Questions to Consider When Buying a Laser Engraving Machine

Before making a purchase, consider these questions to ensure you choose the right machine for your needs:

- What materials will I be engraving? Knowing your material compatibility will guide your machine selection.

- What level of detail do I require? Higher resolution and precision may be necessary for intricate designs.

- How often will I use the machine? Frequency of use impacts the machine’s durability and warranty considerations.

- What is my budget? Balancing cost with features and capabilities is essential.

- Do I need portability or a stationary setup? Machine size and weight can affect its placement and usability.

- Will I need software training