The Art and Science of Laser Engraving Plaques: A Comprehensive Guide

Laser engraving plaques have become a cornerstone in modern craftsmanship, offering unparalleled precision and creativity for a wide range of applications. Whether you’re creating custom awards, personalized signs, or decorative items, laser engravingplaques provide a versatile and efficient solution. This article delves into the world of laser engraving plaques, exploring their benefits, applications, and how to choose the right equipment for your needs.

The Advantages of Laser Engraving Plaques

Laser engraving plaques offer numerous advantages over traditional engraving methods. First and foremost, laser engraving provides unmatched precision, allowing for intricate designs and text that would be nearly impossible to achieve manually. This level of detail ensures that each plaque is not only functional but also a work of art.

Another significant benefit is the ability to customize designs on-the-fly. With laser engraving plaques, you can easily adjust patterns, fonts, and graphics without the need for expensive molds or templates. This flexibility makes it ideal for businesses that require personalized branding or individuals looking to create unique keepsakes.

Additionally, laser engraving is a non-contact process, which means it doesn’t wear down tools over time like traditional engraving methods. This reduces maintenance costs and ensures consistent quality across all projects. Furthermore, the use of lasers minimizes material waste, making it an environmentally friendly option for manufacturers.

Applications of Laser Engraving Plaques

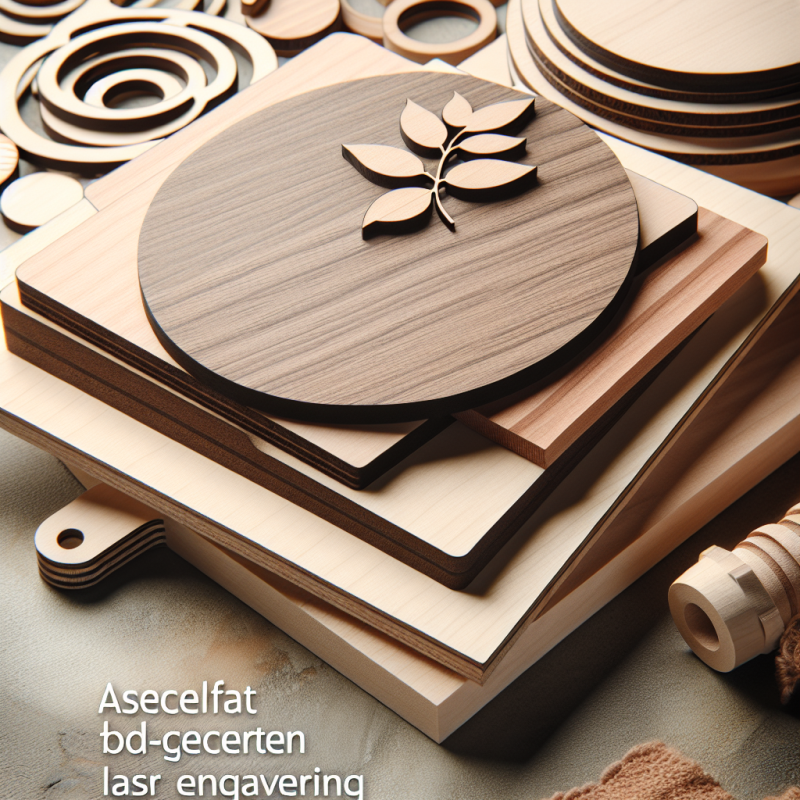

Laser engraving plaques have a wide range of applications across various industries. Some common uses include:

- Awards and recognition plaques: Perfect for creating custom trophies, certificates, and medals with intricate designs.

- Signage and: Ideal for producing durable signs for businesses, landmarks, or public spaces.

- Decorative items: From personalized jewelry boxes to wall art, laser engravingplaques can add a touch of elegance to any space.

- Furniture and home decor: Engrave custom designs on wood furniture, cutting boards, or decorative panels.

These applications highlight the versatility of laser engraving plaques, making them a valuable tool for both small-scale creators and large-scale manufacturers.

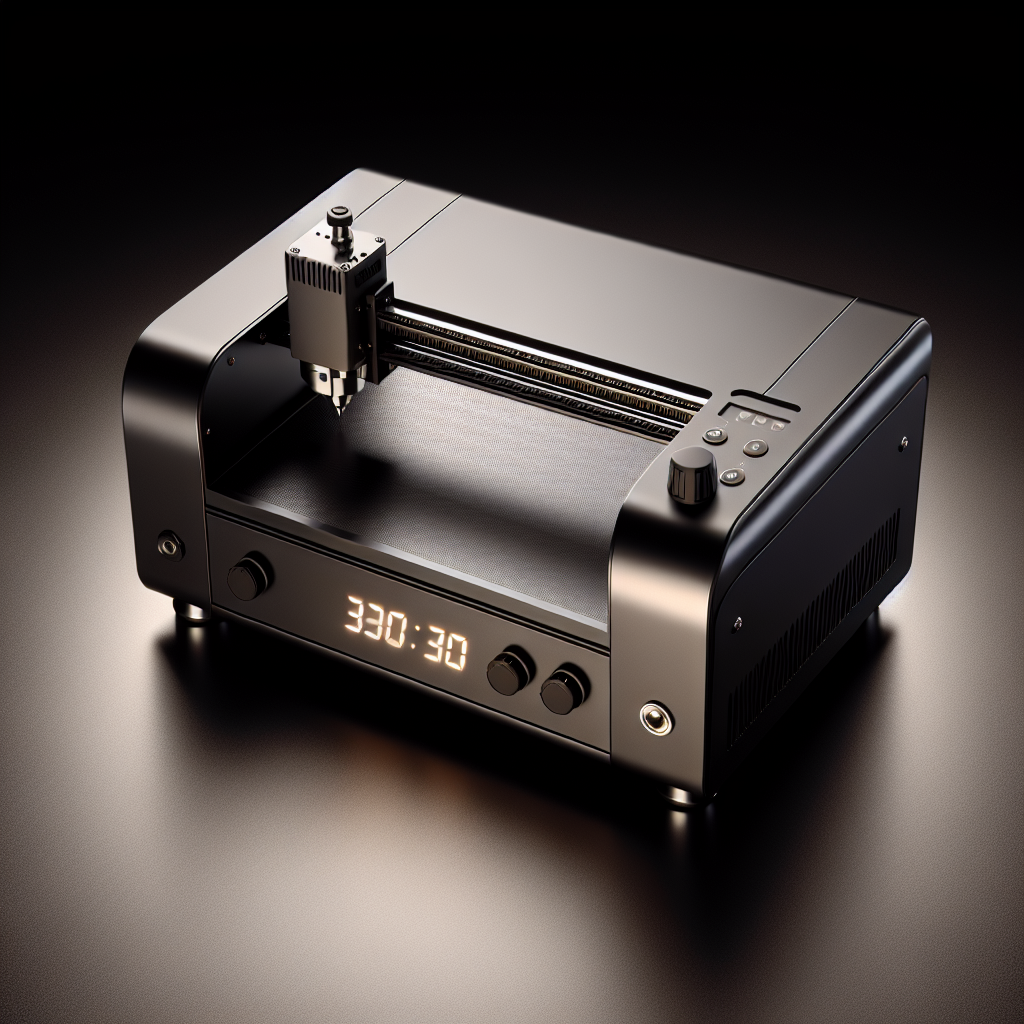

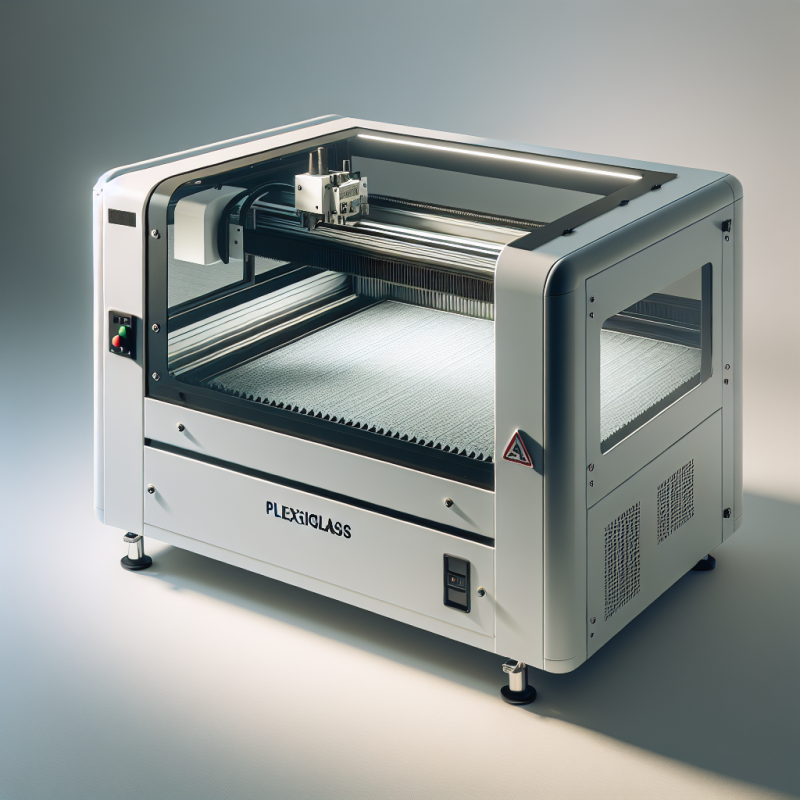

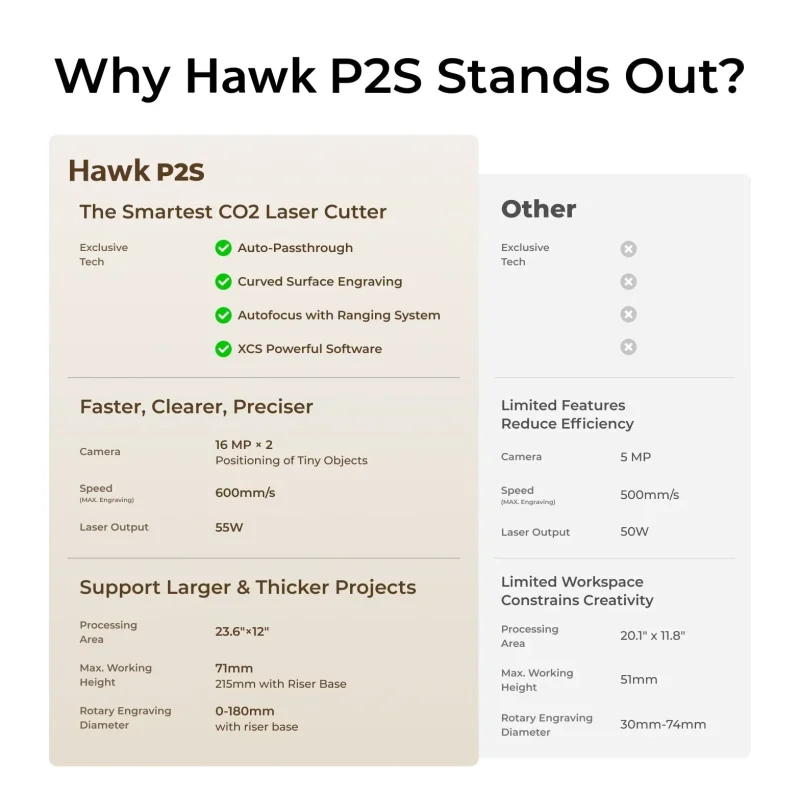

Choosing the Right Laser Engraving Plaque Machine

Selecting the right laser engraving plaque machine is crucial to achieving high-quality results. There are several factors to consider when making your choice:

- Power output: Higher power lasers are better suited for thicker materials, while lower power lasers work well for delicate engravings.

- Material compatibility: Ensure the machine can handle the types of materials you plan to engrave, such as wood, metal, or plastic.

- Software integration: Look for machines that are compatible with popular design software like Adobe Illustrator or CorelDRAW.

- Ease of use: Consider the learning curve and user-friendliness of the machine, especially if you’re new to laser engraving.

One excellent option for those looking to get started is the . This machine combines precision with versatility, making it suitable for a wide range of projects.

Maintenance Tips for Laser Engraving Plaques

Proper maintenance is essential to ensure the longevity and optimal performance of your laser engraving plaque machine. Here are some tips to keep your equipment in top shape:

- Clean regularly: Dust and debris can accumulate on the laser head and optics, reducing efficiency over time. Use compressed air or a soft cloth to clean these areas.

- Check calibration: Periodically verify that the machine is properly calibrated to ensure accurate engravings.

- Replace consumables: Laser engraving plaques require regular replacement of certain components, such as lenses and belts. Consult your user manual for specific recommendations.

By following these maintenance tips, you can extend the lifespan of your laser engraving plaque machine and maintain high-quality output for years to come.

Challenges in Laser Engraving Plaques

While laser engraving plaques offer many benefits, there are also challenges that users may encounter. One common issue is material warping, especially with thin or delicate materials. To mitigate this, ensure the workpiece is securely clamped and use appropriate cooling methods if necessary.

Another challenge is achieving consistent depth in engravings, particularly on uneven surfaces. This can be addressed by adjusting the laser power and speed settings based on the material and desired outcome. Experimentation and practice are key to mastering these adjustments.

Frequently Asked Questions About Laser Engraving Plaques

Here are some frequently asked questions about laser engraving plaques:

- Q: Can I engrave on metal with a laser engraver?

A: Yes, many laser engraving machines are capable of engraving on metal. However, ensure the machine is rated for the type of metal you plan to use. - Q: What materials are best suited for laser engraving?

A: Common materials include wood, acrylic, leather, and some metals. Avoid using materials with reflective or high-moisture content, as they may not work well with lasers. - Q: How long does it take to learn how to use a laser engraver?

A: With practice, you can become proficient in a matter of weeks. Start with simple projects and gradually move on to more complex designs.

Conclusion

Laser engraving plaques have revolutionized the way we create custom designs and personalized items. Their precision, versatility, and efficiency make them an invaluable tool for both hobbyists and professionals alike. By understanding the benefits, applications, and challenges of laser engravingplaques, you can unlock your creative potential and produce stunning works of art.

If you’re ready to take the plunge into the world of laser engraving, consider investing in a high-quality machine like the . With proper care and technique, you’ll be well on your way to creating masterpiece after masterpiece.