The Power of 3D Laser Engraving: Exploring Its Capabilities and Applications

Introduction

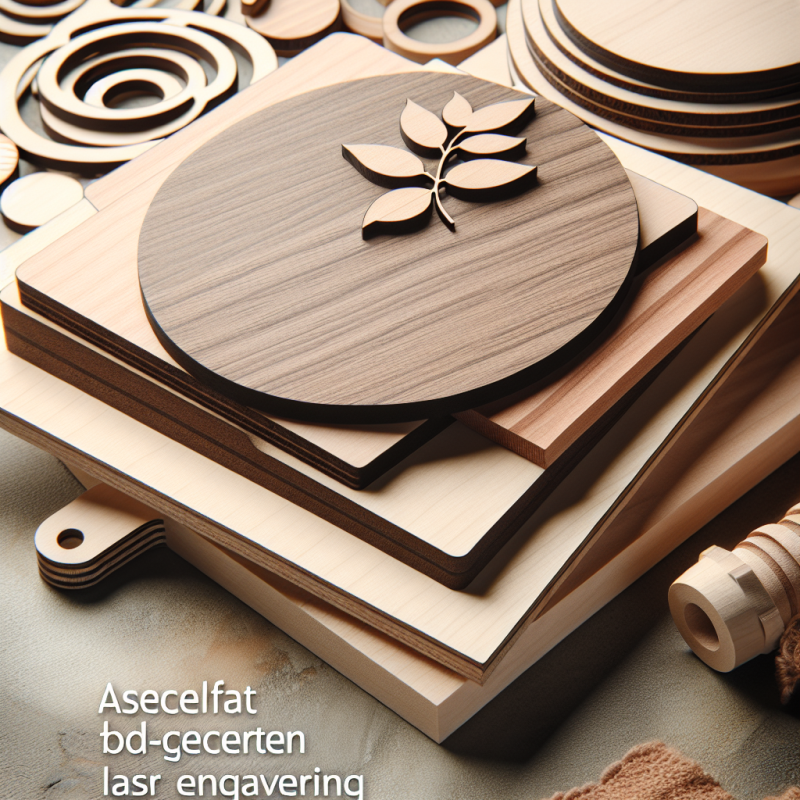

Laser engraving has revolutionized the way we create intricate designs, patterns, and textures on various materials. Among the many advancements in this field, 3D laser engraving stands out as a cutting-edge technology that combines precision, creativity, and versatility. Whether you’re working with metals, plastics, wood, or glass, 3D laser engraving offers unparalleled flexibility and detail. In this article, we’ll explore the fundamentals of 3D laser engraving, its applications, benefits, and how it can be a game-changer for your projects.

What is 3D Laser Engraving?

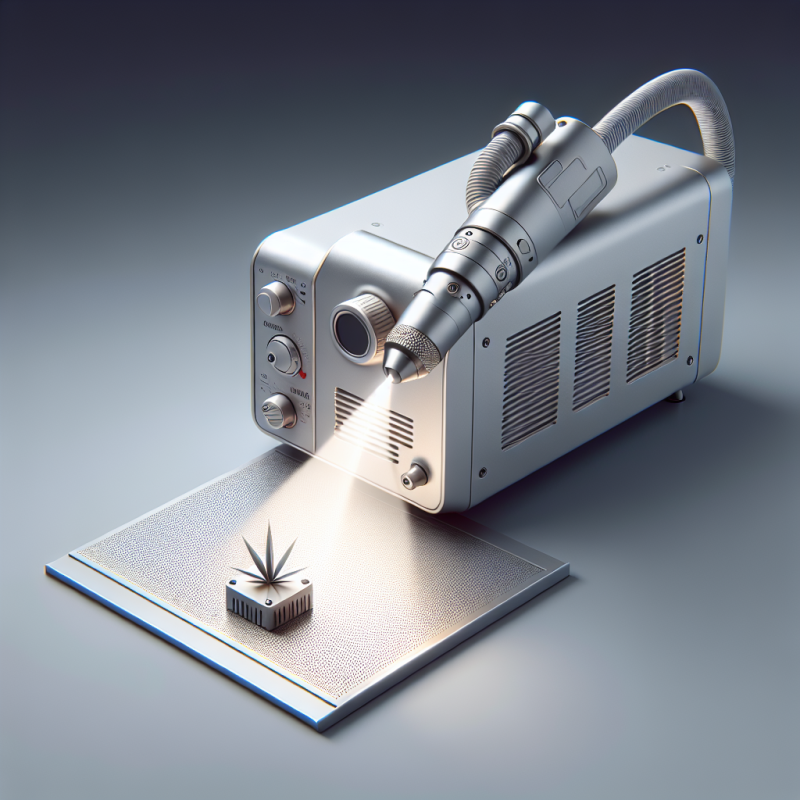

3D laser engraving is a process that uses high-powered lasers to etch or cut intricate designs into the surface of a material. Unlike traditional 2D laser engraving, which operates on a single plane, 3D laser engraving allows for depth and dimensional effects. This technology enables the creation of complex shapes, patterns, and textures that pop with detail and realism.

The process involves using a laser engraver machine equipped with advanced software to control the laser’s movements. The laser beam is directed by mirrors and lenses to focus on specific points of the material, removing or altering the surface layer to create the desired design. This level of precision makes 3D laser engraving ideal for both industrial and artistic applications.

Question: What materials are best suited for 3D laser engraving?

How Does 3D Laser Engraving Work?

To understand how 3D laser engraving works, let’s break it down into its core components:

- Laser Source: The laser emits a concentrated beam of light that heats and vaporizes the material surface.

- Software Control: Advanced software programs guide the laser’s movements, ensuring precise execution of complex designs.

- Focusing Optics: Lenses and mirrors focus the laser beam to a pinpoint, enabling intricate detailing.

- Material Interaction: The laser interacts with the material, removing or altering it to create the desired effect.

The machine’s software plays a crucial role in achieving high-quality results. Programs like XTool Laser Engraver () offer intuitive interfaces and powerful tools for designing and executing 3D engravings. These systems allow users to import CAD files, adjust settings, and preview their designs before printing.

Question: How does the software ensure precision in 3D laser engraving?

Applications of 3D Laser Engraving

The versatility of 3D laser engraving makes it applicable across a wide range of industries. Here are some of its most common uses:

- Jewelry Design: Create intricate patterns, gemstone settings, and custom engravings on precious metals like gold, silver, and platinum.

- Furniture Manufacturing: Add decorative elements, logos, or personal messages to wooden surfaces with exceptional detail.

- Medical Devices: Engrave precise markings and identifiers on surgical instruments, implants, and other medical equipment.

- Automotive Industry: Customize dashboards, trim pieces, and engine components with high-quality engravings.

- Art and Craft: Produce detailed sculptures, decorative items, and personalized gifts using a variety of materials.

The ability to work on multiple materials and create three-dimensional effects makes 3D laser engraving a favorite among artists, manufacturers, and hobbyists alike. With the right equipment, such as the machine, you can unlock endless possibilities for your projects.

Advantages of 3D Laser Engraving

There are several reasons why 3D laser engraving has become a preferred method for precision manufacturing and artistic expression:

- High Precision: The focused laser beam ensures intricate details are captured with accuracy, even on small surfaces.

- Versatility: Works on a wide range of materials, including metals, plastics, wood, glass, and stone.

- Speed: Modern laser engravers can complete complex designs in minutes, reducing production time.

- Eco-Friendly: Minimal material waste compared to traditional engraving methods.

- Durability: The engraved markings are resistant to wear and tear, ensuring long-lasting results.

These advantages make 3D laser engraving a cost-effective and sustainable solution for various applications. Whether you’re creating custom jewelry or industrial components, the technology delivers exceptional quality and efficiency.

Challenges in 3D Laser Engraving

While 3D laser engraving offers numerous benefits, there are some challenges to consider:

- High Initial Cost: Purchasing a high-quality laser engraver machine can be expensive.

- Material Limitations: Some materials may require special handling or additional precautions due to their reflective properties or melting points.

- Complexity of Design: Creating intricate 3D designs requires advanced software skills and a good understanding of laser engraving techniques.

However, these challenges can be overcome with proper training, investment in quality equipment like the machine, and continuous learning about best practices.

Tips for Getting Started with 3D Laser Engraving

If you’re new to 3D laser engraving, here are some tips to help you get started:

- Invest in Quality Equipment: Choose a reliable laser engraver machine and software combination, such as the system.

- Start with Simple Designs: Practice on basic patterns and gradually move to more complex projects as you gain experience.

- Experiment with Materials: Test different materials to understand their properties and how they respond to laser engraving.

- Follow Safety Guidelines: Always wear protective gear and operate the machine in a well-ventilated area to avoid hazards.

By following these tips, you can maximize your success with 3D laser engraving and create stunning, high-quality projects.

The Future of 3D Laser Engraving

As technology continues to evolve, 3D laser engraving is expected to become even more advanced. Innovations such as AI-driven software, higher-powered lasers, and hybrid systems that combine engraving with other manufacturing processes are on the horizon.

These advancements will likely expand the applications of 3D laser engraving, making it accessible to an even broader range of industries and users. Whether you’re a professional artist or a small business owner, staying updated with the latest developments in this field can open up new opportunities for creativity and productivity.

Frequently Asked Questions

Question: Can I use 3D laser engraving on non-metal materials?

Yes! 3D laser engraving is compatible with a variety of materials, including wood, plastic, glass, and stone. The choice of material depends on the desired outcome and the properties required for your project.

Question: How long does it take to learn 3D laser engraving?

The learning curve varies depending on your prior experience with design software and manufacturing processes. With dedicated practice and access to resources, you can become proficient in 3D laser engraving within a few weeks.

Conclusion

3D laser engraving is a powerful tool that combines precision, versatility, and creativity. Whether you’re looking to create custom art pieces or industrial components, this technology offers unmatched capabilities for achieving your vision.

By investing in high-quality equipment like the machine and staying informed about best practices, you can unlock the full potential of 3D laser engraving and take your projects to new heights.

Question: What is the best way to clean a laser-engraved surface?

Cleaning methods vary depending on the material. For metal surfaces, a soft cloth or mild soap solution can be used. Always test a small area first to ensure the cleaning method doesn’t damage the engraved design.