The Precision of Laser Engraving Copper: Exploring Its Applications and Benefits

Laser engraving copper has become a popular method for creating intricate designs on this versatile metal. With its high precision and adaptability, laser engraving offers a range of advantages over traditional methods. In this article, we will delve into the process, benefits, challenges, and applications of laser engraving copper, while also addressing common questions about this technique.

What is Laser Engraving?

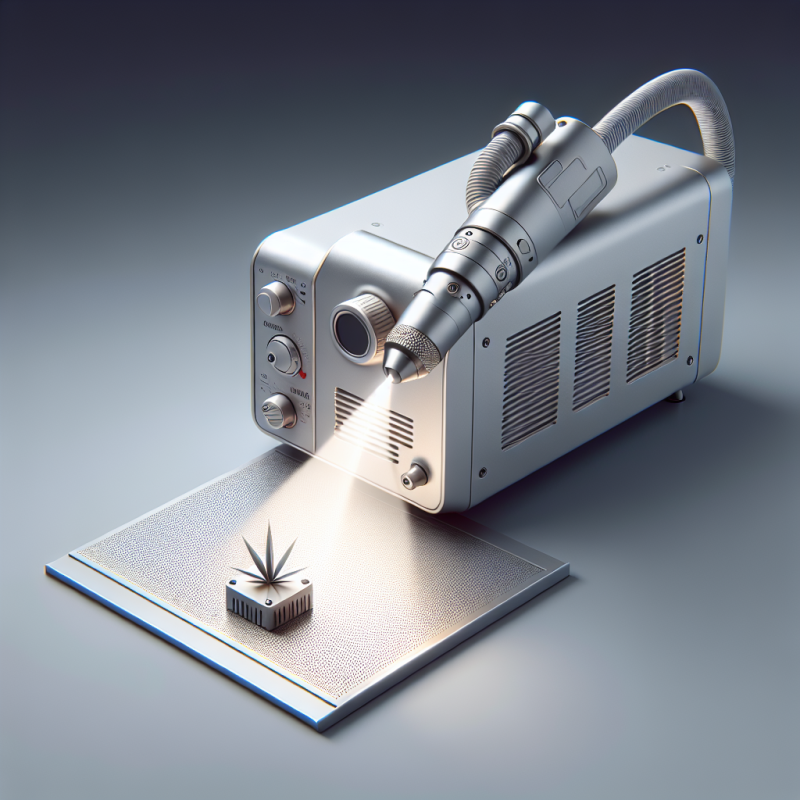

Laser engraving is a cutting-edge manufacturing process that uses a focused beam of light to etch or cut materials. Unlike traditional engraving methods, which often involve mechanical tools, laser engraving offers unparalleled precision and speed. The process involves directing a high-powered laser at the material’s surface, where the energy from the laser melts, burns, or vaporizes the material to create designs or patterns.

Advantages of Laser Engraving Copper

Copper is a unique material that lends itself well to laser engraving due to its thermal properties and malleability. Here are some key advantages of using this method:

- Precision: Laser engraving allows for intricate details, making it ideal for creating complex patterns or text on copper surfaces.

- Speed: Compared to manual engraving, laser engraving is much faster, especially when working with large batches of products.

- Versatility: Copper’s conductivity and reflectivity make it a challenging material for some processes, but lasers can handle these properties effectively.

- Durability: The engraved designs on copper are long-lasting and resistant to wear, making them suitable for both decorative and functional applications.

Challenges in Laser Engraving Copper

While laser engraving copper offers many benefits, there are also some challenges to consider:

- Thermal Expansion: Copper has a high thermal expansion coefficient, which can cause warping or deformation if not properly managed during the engraving process.

- Material Thickness: Thicker copper sheets may require multiple passes or higher-powered lasers to achieve the desired depth and clarity in the engraving.

- Equipment Cost: High-quality laser engravers, such as the laser engraving copper machine, can be expensive to purchase or rent.

Applications of Laser Engraving Copper

Laser engraved copper is used in a variety of industries due to its aesthetic appeal and functional properties. Some common applications include:

- Electronics: Copper is widely used in printed circuit boards (PCBs), where laser engraving can create precise traces and components.

- Jewelry: The intricate designs possible with laser engraving make copper a popular choice for creating unique and personalized jewelry pieces.

- Art and Decor: Artists often use laser-engraved copper to create decorative items such as plaques, signs, and wall art.

- Industrial Parts: Copper components in machinery can be engraved with identification numbers, safety warnings, or other important information using this method.

The Process of Laser Engraving Copper

To achieve optimal results when laser engraving copper, it’s essential to follow a well-planned process. Here is an overview of the steps involved:

- Design Creation: Start by creating or importing your design into compatible software. Ensure the design is scalable and suitable for the size and thickness of the copper sheet.

- Laser Setup: Adjust the laser settings, including power level, speed, and focus distance, based on the thickness and type of copper being engraved.

- Engraving: Carefully align the copper sheet under the laser head and begin engraving. Monitor the process to ensure consistent results and avoid overheating or warping.

- Cooling: Use a cooling system or allow the copper to cool naturally after engraving to prevent further deformation or discoloration.

- Finishing: Clean the engraved surface to remove any residue and polish if necessary to achieve the desired finish.

Frequently Asked Questions About Laser Engraving Copper

1. Can laser engraving be used on all types of copper?

Yes, laser engraving can be applied to various forms of copper, including sheets, plates, and even wire. However, the specific settings may need to be adjusted based on the material’s thickness and finish.

2. Is laser engraved copper resistant to corrosion?

While copper itself is naturally corrosion-resistant, the engraved areas may be more susceptible to oxidation over time. Applying a protective coating can enhance durability and maintain the design’s integrity.

3. How detailed can laser engravings on copper be?

Laser engraving offers exceptional detail, capable of producing text as small as 0.5mm in size and intricate patterns with high precision. The level of detail depends on the quality of the laser machine used.

Conclusion

Laser engraving copper is a versatile and efficient method for creating detailed designs on this valuable metal. Despite some challenges, such as thermal expansion and equipment costs, the benefits of precision, speed, and durability make it a preferred choice in various industries. By understanding the process and selecting the right equipment, like the machine, you can achieve stunning results that meet your project’s requirements.