The Ultimate Guide to Etching Laser Cutters: Precision and Efficiency Redefined

Are you looking for a tool that combines precision, speed, and versatility in one package? If so, an might be exactly what you need. In this comprehensive guide, we’ll explore everything you need to know about etching laser cutters, including how they work, their benefits, and how to choose the right one for your needs.

What is an Etching Laser Cutter?

An is a cutting-edge tool designed to create intricate designs and patterns on various materials with unparalleled precision. Unlike traditional cutting methods, which rely on mechanical tools, laser cutters use high-powered lasers to etch or cut through surfaces. This technology is ideal for professionals in industries such as woodworking, metalworking, sign-making, and custom gift creation.

Why choose a laser cutter over traditional methods? The answer lies in its precision and adaptability. Laser cutters can handle complex designs that would be nearly impossible to achieve with manual tools. Additionally, they operate at high speeds, making them suitable for both small-scale projects and large production runs.

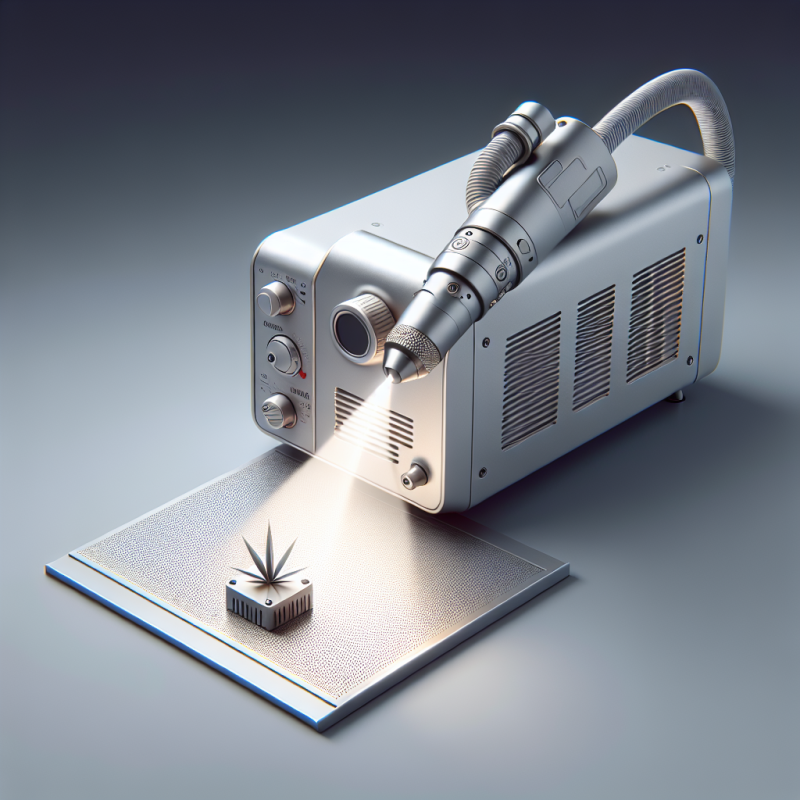

How Does an Etching Laser Cutter Work?

The process of laser cutting involves directing a focused beam of light onto the material being cut or engraved. The laser’s energy is absorbed by the material, causing it to melt, burn, or vaporize at the point of contact. This creates precise cuts or engravings without the need for physical contact between the tool and the material.

Laser cutters use a combination of CNC (Computer Numerical Control) technology and advanced software to guide the laser beam along pre-programmed paths. Here’s a simplified breakdown of how it works:

- The design is created or imported into specialized software.

- The software converts the design into instructions for the laser cutter.

- The CNC system directs the laser beam according to these instructions.

- The laser beam etches or cuts the material based on the programmed pattern.

This process allows for highly accurate and repeatable results, making it a favorite among crafters, manufacturers, and artists alike.

Benefits of Using an Etching Laser Cutter

There are numerous advantages to using an . Let’s explore some of the key benefits:

- Precision and Accuracy: Laser cutters can achieve levels of precision that are unmatched by traditional tools. This makes them ideal for creating intricate designs or performing delicate cuts.

- Speed: Once the design is programmed, laser cutters operate at high speeds, significantly reducing production time compared to manual methods.

- Versatility: Laser cutters can work with a wide range of materials, including wood, metal, plastic, glass, and even fabric. This versatility makes them suitable for diverse applications.

- Minimal Material Waste: Since laser cutting is a non-contact process, there’s no risk of damaging the material during the cutting or engraving process.

Are you wondering how to get started with laser cutting? Many manufacturers offer user-friendly software and guides to help beginners navigate the learning curve. With practice, even those new to laser cutting can achieve professional-level results.

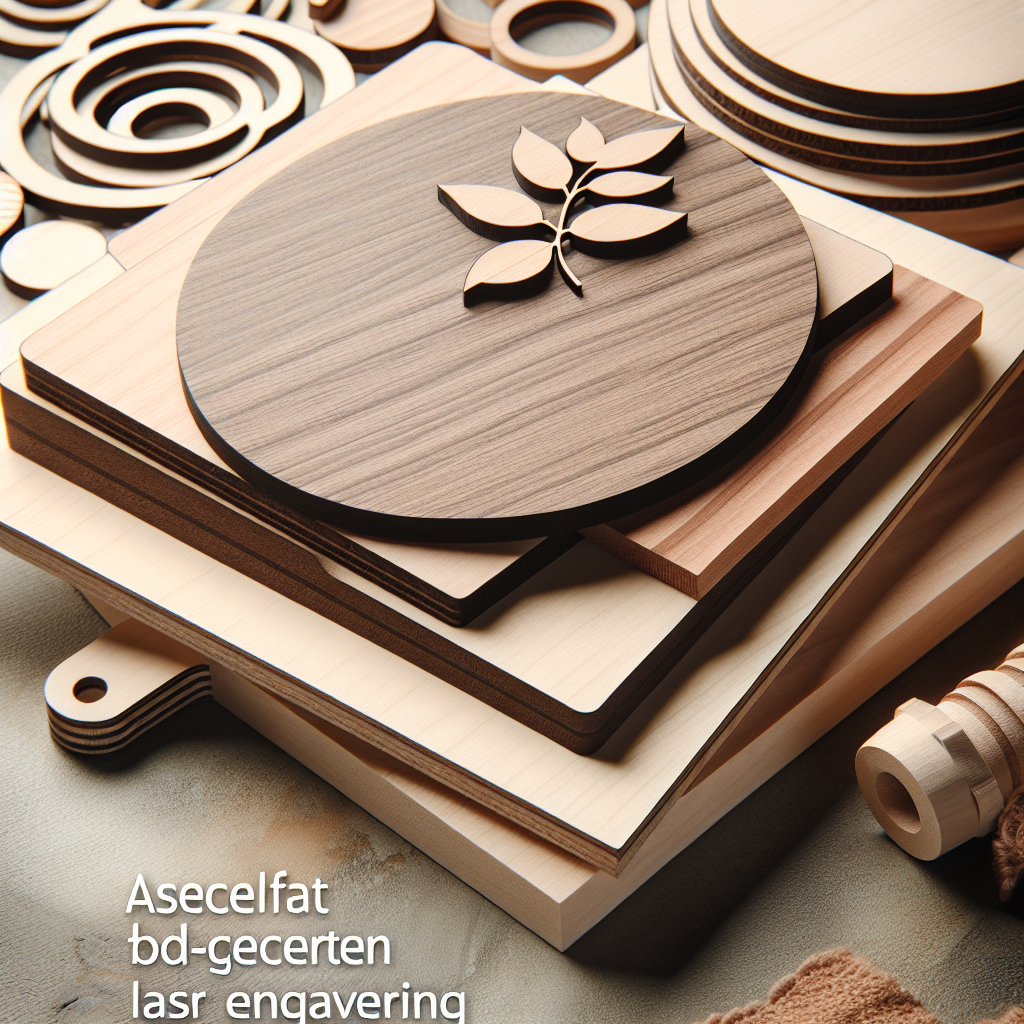

Applications of Etching Laser Cutters

The applications of etching laser cutters are vast and varied. Here are some common uses:

- Woodworking: Engraving intricate designs on wooden furniture, decorative items, or signage.

- Metalworking: Cutting or engraving metal sheets for creating custom signs, jewelry, or industrial parts.

- Sign-Making: Producing high-quality signs with precise lettering and graphics.

- Custom Gifts: Creating personalized items like engraved wooden boxes, nameplates, or photo frames.

- Fabric Cutting: Laser cutting fabric for creating custom designs in textiles or fashion.

What material are you most interested in working with? Whether it’s wood, metal, plastic, or another substrate, an etching laser cutter can likely handle it. Just ensure that the machine is compatible with your chosen material before starting your project.

Choosing the Right Etching Laser Cutter

With so many options available on the market, selecting the right can be overwhelming. Here are some factors to consider:

- Type of Material: Different materials require different types of lasers. For example, CO2 lasers are ideal for cutting wood and plastics, while fiber lasers are better suited for metals.

- Power Output: The power of the laser determines its ability to cut through thicker or harder materials. Higher power output is necessary for industrial applications, while lower power machines may suffice for hobbyist use.

- Build Quality: Look for machines with robust construction and high-quality components to ensure durability and long-term performance.

- User-Friendliness: Consider the ease of setup, operation, and maintenance. User-friendly interfaces and intuitive software can make a significant difference, especially if you’re new to laser cutting.

Are you on a budget? There are affordable options available that still deliver excellent results for small-scale projects. However, investing in a higher-quality machine may save you money in the long run by reducing maintenance and replacement costs.

Maintenance and Safety Tips

Like any precision tool, an etching laser cutter requires proper care and maintenance to ensure optimal performance and longevity. Here are some tips:

- Regular Cleaning: Dust and debris can accumulate on the machine’s optics and surfaces, affecting performance. Clean the machine regularly using compressed air or soft cloths.

- Lens Care: The laser lens is a critical component. Avoid touching it with bare hands and clean it only with specialized lens cleaning solutions.

- Safety Precautions: Always wear appropriate safety gear, such as goggles, when operating the machine. Ensure proper ventilation to avoid inhaling fumes generated during cutting or engraving.

Do you have any questions about maintaining your laser cutter? Refer to the manufacturer’s manual or consult with a professional for guidance.

Conclusion

An is an invaluable tool for anyone looking to bring their creative visions to life with precision and efficiency. Whether you’re a hobbyist, artist, or professional, this technology offers endless possibilities for your projects.

Are you ready to take the plunge and invest in a laser cutter? With the right machine and a little practice, you’ll be creating stunning designs in no time. Happy crafting!