The Ultimate Guide to Laser Cutter Metal: Precision Engraving Made Easy

Laser cutter metal machines have revolutionized the way we approach precision engraving and cutting in various industries. Whether you’re a professional artist, a small business owner, or a hobbyist, these machines offer unparalleled versatility and accuracy. In this article, we’ll dive into everything you need to know about laser cutter metal, including how they work, their applications, benefits, and how to choose the right one for your needs.

How Does a Laser Cutter Metal Machine Work?

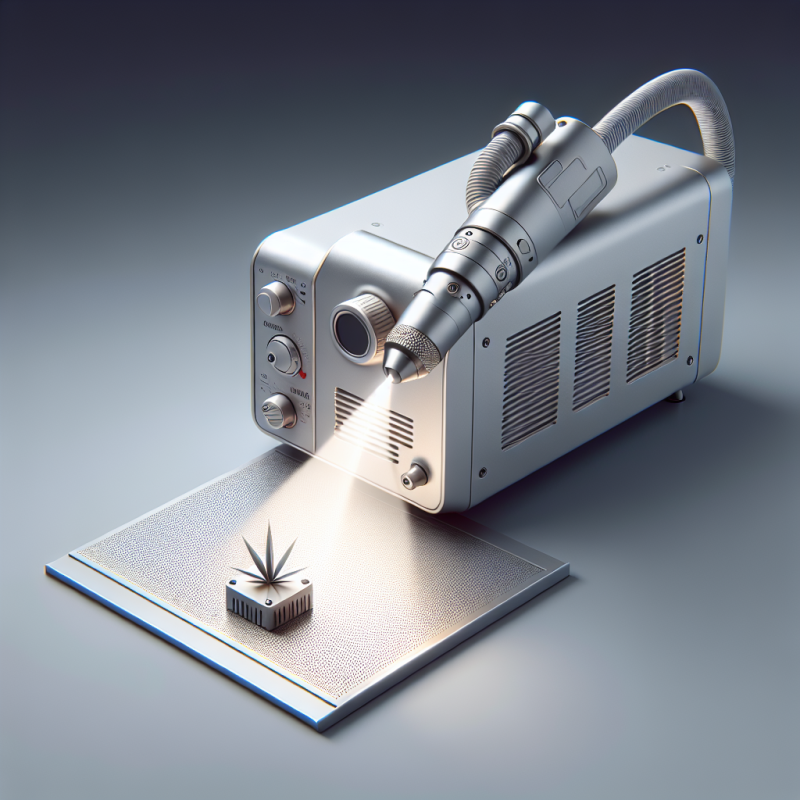

A laser cutter metal machine uses advanced laser technology to cut or engrave materials with extreme precision. The process involves focusing a high-powered laser beam onto the surface of the material, which heats it up and either melts or vaporizes it, creating clean and precise cuts or engravings. Unlike traditional cutting methods, laser cutter metal machines operate at high speeds while maintaining exceptional accuracy.

The machine typically uses a diode laser, which is known for its reliability and efficiency. The laser beam is guided by computer-controlled optics, allowing for intricate designs and patterns to be cut or engraved with ease. This makes it an ideal tool for industries that require precision and detail, such as jewelry making, signage production, and industrial manufacturing.

Applications of Laser Cutter Metal Machines

Laser cutter metal machines are incredibly versatile and can be used in a wide range of applications. Here are some of the most common uses:

- Jewelry Making: Create intricate designs on precious metals like gold, silver, and platinum.

- Signage Production: Engrave custom letters and logos onto metal signs for businesses and public spaces.

- Medical Devices: Precision engraving of medical instruments and implants.

- Automotive Industry: Cut and engrave parts for cars, motorcycles, and other vehicles.

- Artistic Creations: Produce unique metal art pieces with intricate details.

These machines are also used in the electronics industry to cut and engrave circuit boards, as well as in the aerospace sector for creating lightweight, precision components. The possibilities are endless!

Benefits of Using a Laser Cutter Metal Machine

Investing in a laser cutter metal machine offers numerous benefits that can enhance your productivity and creativity. Some of the key advantages include:

- Precision and Accuracy: The laser beam ensures clean, precise cuts and engravings with minimal material waste.

- Versatility: Works on a variety of materials, including metals, plastics, wood, and glass.

- Speed: High-speed processing allows for quick turnaround times on even the most complex designs.

- Durability: The machine is built to last, with robust components that ensure long-term performance.

In addition to these benefits, laser cutter metal machines are easy to operate and can be integrated with computer software for design and programming. This makes them accessible even to those who are not highly skilled in machining or engraving.

Choosing the Right Laser Cutter Metal Machine

With so many options available, selecting the right laser cutter metal machine can be overwhelming. Here are some factors to consider when making your choice:

- Power Output: Higher power output means greater cutting and engraving capabilities, especially for thicker materials.

- Material Compatibility: Ensure the machine can handle the types of materials you’ll be working with.

- Software Integration: Look for machines that are compatible with popular design software like CAD and Illustrator.

- Budget: Determine your budget and look for a machine that offers the best value for your money.

If you’re looking for a reliable and high-quality laser cutter metal machine, consider checking out the options available at [insert link to product page]. Their machines are designed with precision, durability, and versatility in mind, making them perfect for both small-scale and large-scale projects.

Maintenance and Care for Laser Cutter Metal Machines

To ensure your laser cutter metal machine performs at its best for years to come, proper maintenance is essential. Here are some tips:

- Clean the Machine Regularly: Dust and debris can interfere with the machine’s performance, so clean it after each use.

- Check the Laser Beam: Ensure the laser beam is properly focused and aligned for optimal cutting and engraving.

- Calibrate Regularly: Calibrate the machine to maintain accuracy and prevent errors in cuts or engravings.

By following these simple maintenance tips, you can extend the life of your laser cutter metal machine and ensure it continues to deliver high-quality results.

Frequently Asked Questions About Laser Cutter Metal Machines

1. Can a laser cutter metal machine cut through all types of metals?

While most laser cutter metal machines can handle common metals like steel, aluminum, and brass, they may not be suitable for extremely thick or high-hardness materials. Always check the specifications of the machine before making your purchase.

2. Is it difficult to learn how to use a laser cutter metal machine?

No, most machines are designed with user-friendly interfaces and come with comprehensive training manuals. With some practice, you can become proficient in operating the machine quickly.

3. How much does a laser cutter metal machine cost?

The cost of a laser cutter metal machine varies depending on its power, size, and additional features. Basic models may start around $500, while high-end industrial machines can cost upwards of $10,000 or more.

4. Can I use a laser cutter metal machine for non-metal materials?

Absolutely! Many laser cutter metal machines are capable of cutting and engraving non-metal materials like wood, plastic, and glass. This makes them an incredibly versatile tool for various projects.

Conclusion

A laser cutter metal machine is a powerful addition to any workshop or studio, offering precision, versatility, and efficiency that traditional cutting methods simply can’t match. Whether you’re working on small-scale projects or large industrial applications, these machines are sure to enhance your productivity and creativity.

If you’re ready to take your engraving and cutting capabilities to the next level, consider investing in a high-quality laser cutter metal machine. With the right machine, you’ll be able to tackle any project with confidence and precision. Visit [insert link to product page] today to explore their selection of top-tier laser cutter machines!