The Ultimate Guide to Laser Engraver Cutters

Are you searching for a versatile tool that can handle both precision cutting and intricate engraving? Look no further than the . This innovative device has become a game-changer in various industries, from woodworking to metalworking, offering unparalleled accuracy and efficiency. In this comprehensive guide, we’ll explore everything you need to know about laser engraver cutters, their applications, benefits, and how to choose the right one for your needs.

What is a Laser Engraver Cutter?

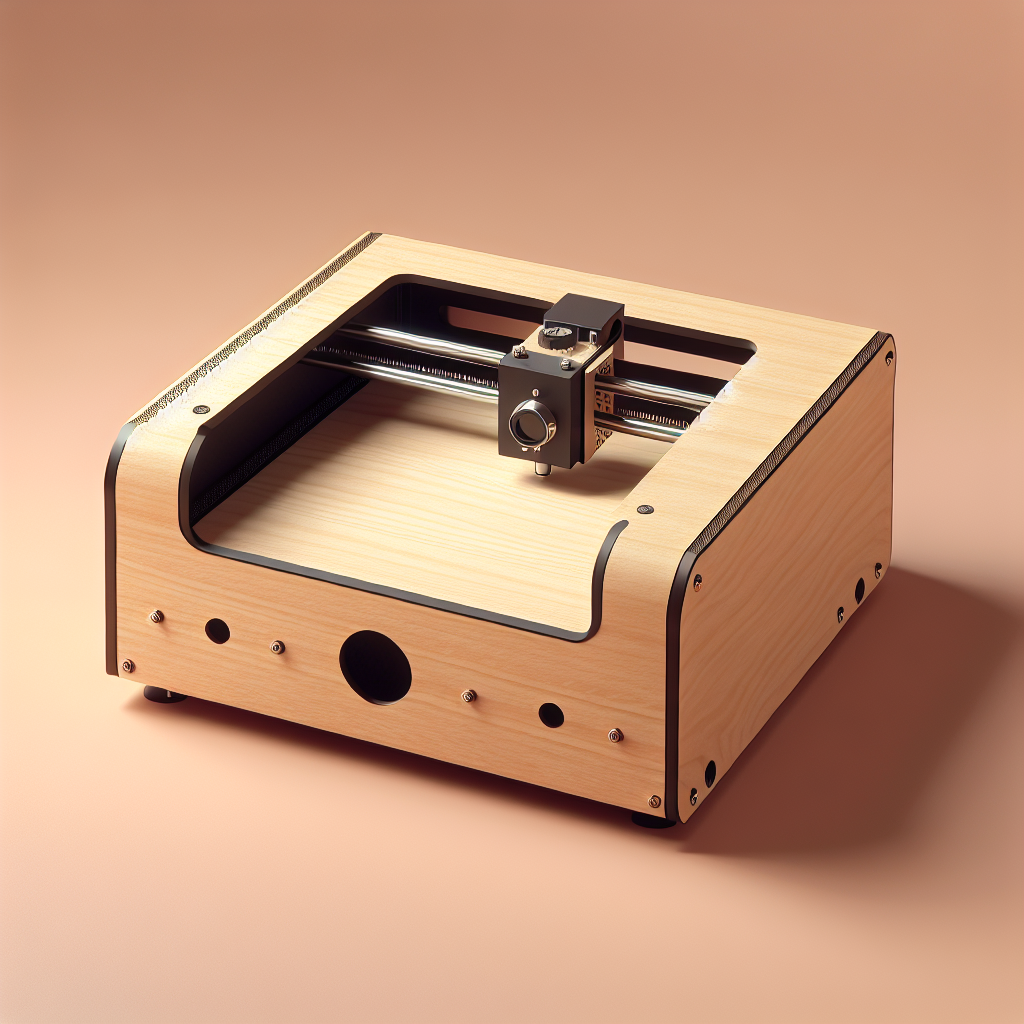

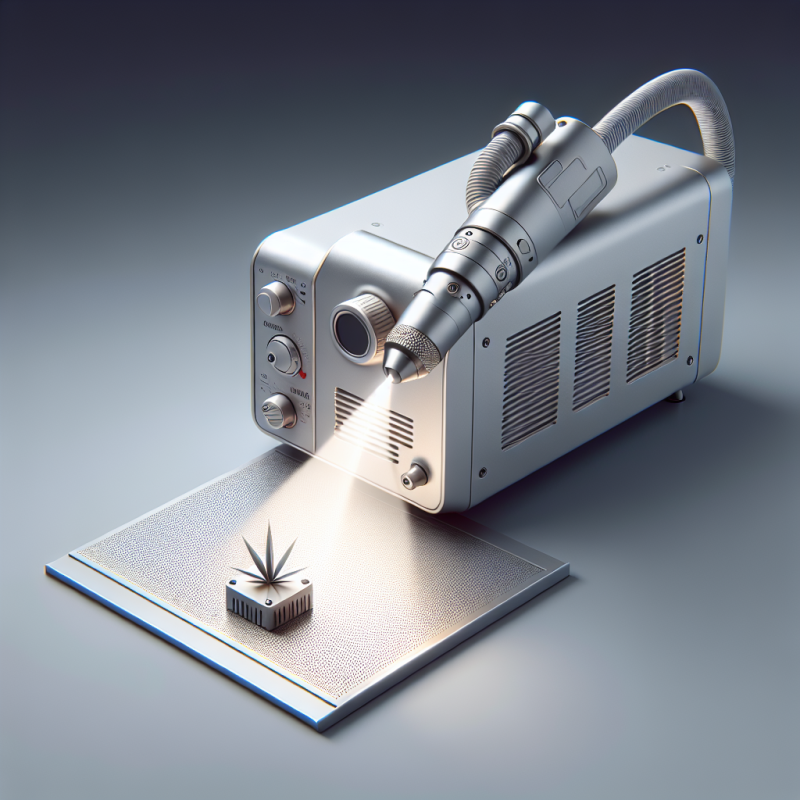

A is a multi-functional machine designed to etch or cut materials with laser technology. Unlike traditional tools, this device uses focused light beams to create precise designs, patterns, and text on various surfaces. The process involves directing the laser beam across the material at high speeds, ensuring clean cuts and sharp engravings. This technology is widely used in industries like jewelry making, signage production, and custom craft projects.

The key advantage of a lies in its ability to work with a wide range of materials. Whether you’re cutting through wood, metal, plastic, or even glass, this machine delivers consistent results. Its precision ensures that even the most intricate designs are replicated accurately, making it an indispensable tool for creative professionals and hobbyists alike.

Applications of Laser Engraver Cutters

Laser engraver cutters have a vast array of applications across different fields. Here are some of the most common uses:

- Cutting and engraving custom designs on wood, acrylic, and metal.

- Creating signage and plaques with high-quality text and graphics.

- Engraving logos and patterns on jewelry pieces.

- Producing precise cuts for model making and prototyping.

- Etching intricate details on decorative items like vases, clocks, and furniture.

The versatility of the makes it suitable for both small-scale projects and large industrial operations. Its ability to handle multiple materials ensures that it can adapt to a wide range of creative and practical needs.

Benefits of Using a Laser Engraver Cutter

There are numerous reasons why professionals and hobbyists alike prefer laser engraver cutters over traditional tools:

- Precision and Accuracy: The laser beam ensures that every cut and engraving is precise, eliminating the risk of human error.

- Versatility: Capable of working with various materials, this machine offers endless creative possibilities.

- Speed: Laser cutting and engraving are much faster than manual methods, saving time and increasing productivity.

- Cost-Effective: With minimal material waste and the ability to handle small batches efficiently, this machine is a long-term investment that pays for itself over time.

If you’re wondering whether a is the right choice for your projects, consider its ability to handle both large-scale production and small, detailed tasks with ease. It’s a tool that truly offers something for everyone.

How to Choose the Right Laser Engraver Cutter

Selecting the perfect depends on your specific needs and budget. Here are some key factors to consider:

- Material Compatibility: Ensure the machine can handle the materials you plan to work with, such as wood, metal, or plastic.

- Laser Power: Higher wattage lasers offer greater cutting and engraving capabilities but may require more powerful systems.

- Software Compatibility: Look for machines that support popular design software like Adobe Illustrator or CorelDRAW.

- Budget: Determine your budget and compare features to find a machine that offers the best value for money.

Investing in a high-quality is an excellent way to elevate your projects and achieve professional-level results. With its precision, versatility, and efficiency, this tool is a must-have for anyone looking to take their crafting or production capabilities to the next level.

Frequently Asked Questions

Q: Can I use a laser engraver cutter for both cutting and engraving?

A: Yes, most laser engraver cutters are designed to handle both functions. The machine can switch between modes depending on the task at hand.

Q: Is it safe to operate a laser engraver cutter?

A: When used correctly and with proper safety precautions, such as wearing protective eyewear and ensuring good ventilation, operating a is safe. Always follow the manufacturer’s guidelines to minimize risks.

Q: What materials can I use with a laser engraver cutter?

A: Common materials include wood, acrylic, plastic, glass, and metal. Some machines may require additional settings or adjustments for different materials.

Conclusion

If you’re looking to add precision and creativity to your projects, a is an excellent investment. Its ability to handle both cutting and engraving with exceptional accuracy makes it a versatile tool for professionals and hobbyists alike. By considering your specific needs and budget, you can find the perfect machine to bring your creative visions to life. Whether you’re crafting custom jewelry or producing signage, this innovative device will undoubtedly elevate your work to new heights.